Operating a forklift requires a thorough understanding of the machine’s various characteristics. Its capacity is one of the most critical pieces of information. How can this data be deciphered and used effectively? The capacity of your forklift is determined by several factors, such as the maximum weight it can lift and the height at which it can do so safely. Several concepts are related to a forklift’s capacity, such as rated capacity, residual capacity, and the load center. Discover the various characteristics of your forklift with Vallée.

Each forklift has its own lifting capacity

Lifting capacity is an important criterion when choosing your forklift. Depending on its design and use, each model offers its own capacity in terms of maximum load:

- The rough terrain forklift is a machine designed for handling in tough outdoor environments such as construction sites, mines, or industrial yards. Equipped with all-wheel drive, it provides excellent stability on uneven, slippery, or muddy surfaces. Its agility allows it to maneuver easily in tight spaces while ensuring safety and efficiency. Its lifting capacity varies by model, generally ranging from 3,000 to 60,000 pounds, with industrial models such as those from the Vallée brand capable of lifting up to 55,000 pounds.

- The reach truck: it lifts loads to great heights in tight spaces. Its lifting capacity generally decreases as the height increases.

- The electric forklift: quiet and non-polluting, this vehicle is more suited to indoor environments. Its lifting capacity is often moderate, but some models can handle heavy loads. At Vallée, an all-terrain electric model will be launched on the market in 2026. The customer will be able to choose the battery they need depending on the intended use. Discover your electric model: the Vallée 4DA 25-XRT. This model is designed to produce zero emissions.

- The gas or diesel forklift: powerful and robust, this category of vehicles offers the highest lifting capacity, ideal for very heavy outdoor loads.

- Other compact models: the three-wheel forklift and the stacker are intended for lighter loads and medium lifting heights.

Various technical factors, such as lift height, mast options and accessories, mast type, or weight distribution, directly influence the actual load capacity.

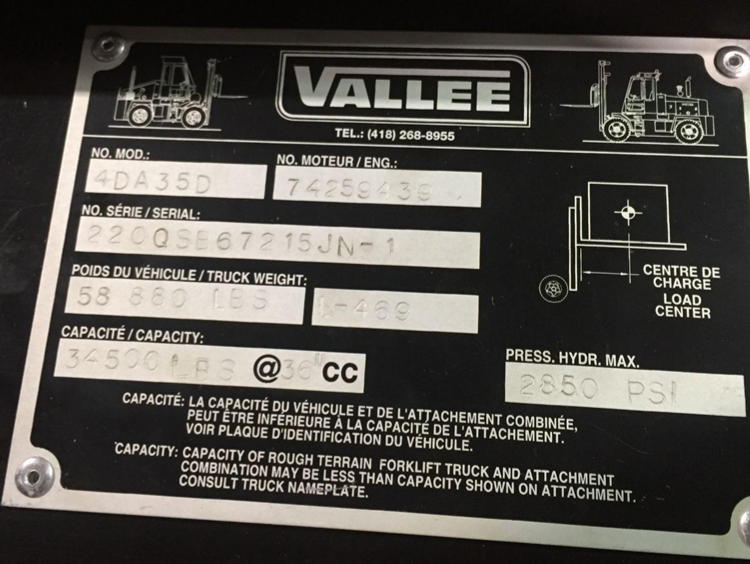

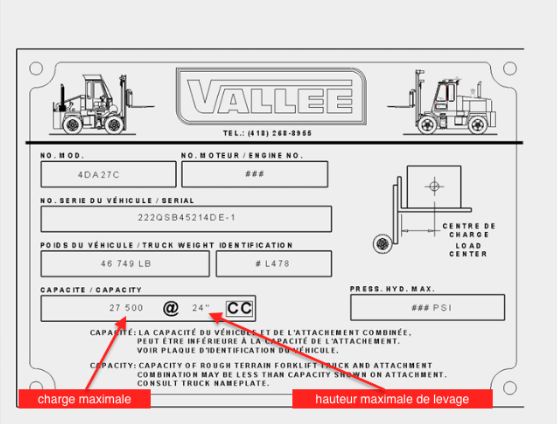

Identifying lifting capacities through regulatory plates

Two plates are always present on a forklift and provide key information about its lifting capacities:

- The capacity plate indicates the residual capacity, that is, the load that the forklift can actually handle depending on its configuration.

- The nameplate mentions the rated capacity, defined as the maximum load the forklift can lift without any accessory and at a standard height of 3.30 meters.

This plate may also include other information, such as chassis details.

What is a Forklift’s Rated Capacity?

The rated capacity of a forklift is one of the most critical safety features you must know about your vehicle. Often expressed in pounds and sometimes kilograms, it represents the maximum load the forklift can safely lift when the mast is vertical, at a given height, and a standardized distance.

This distance refers to the horizontal gap between the vertical face of the forks and the load’s center of gravity. The rated capacity is determined by considering a standardized center of gravity, which varies depending on the forklift’s capacity.

Knowing your forklift’s rated capacity is essential because exceeding it can result in tipping over. Choosing a forklift with a rated capacity that matches the loads you will handle also optimizes material handling and minimizes risks.

What to Know About Actual Capacity?

A forklift’s capacity represents the maximum weight it can safely lift in a given situation. The capacity may be lower than the rated capacity listed on the forklift’s data plate. Unlike the rated capacity, which is a fixed value, the exact capacity varies based on several factors:

- Lift height directly affects the actual capacity. As the load is lifted higher, the actual capacity decreases. For example, a forklift that can lift 10,000 lbs at a low height may only lift 6,000 lbs at its maximum height.

- Weight distribution also plays a role. If the load is not well balanced, or if its center of gravity is far from the forks, the actual capacity can decrease because the forklift becomes less stable.

- Accessories used also impact the actual capacity. Additional equipment, such as clamps or fork extensions, reduces the load the forklift can lift.

- Environmental conditions like uneven ground or slopes can also reduce the forklift’s actual capacity by affecting its stability.

Note: Il n’existe pas de formule simple pour calculer la capacité de levage réelle. Chaque situation est spécifique et nécessite une évaluation personnalisée.

The Center of Gravity

The center of gravity is crucial to a forklift’s load capacity. It represents the balance point of the forklift and its load. If this center of gravity is not aligned correctly with the forklift’s support surface, the risk of sideways or forward tipping increases significantly.

Each forklift has a load capacity chart, also known as a center of gravity diagram, that indicates the lifting capacity based on height and the center of gravity’s position. Correctly reading and understanding this chart is essential for safe forklift operation.

The center of gravity shifts depending on the load being carried. The heavier and farther from the mast, the more the load is, the more the center of gravity moves forward, reducing stability. Correctly positioning and centring the load, along with an accurate reading of the load capacity chart, are crucial for ensuring the safe use of the forklift. The load capacity decreases as the distance between the load and the mast increases.

How Do Attachments Affect Residual Capacity?

The residual capacity of a forklift indicates the maximum load it can support at a given lift height, considering all factors affecting its stability, including installed attachments. This figure also corresponds to the actual capacity in a specific situation, which may be lower than the rated capacity listed on the data plate.

Installing additional attachments such as rotators, clamps, or side shifters alters the weight distribution on the forklift, directly influencing the residual capacity. Each attachment has its own rated capacity and center of gravity. These parameters must be considered when calculating the forklift’s residual capacity with the installed attachment. For example, although fork extensions are helpful in handling longer loads, they increase the distance between the load’s center of gravity and the forklift’s mast. Using this attachment reduces the forklift’s residual capacity.

Reading the Data Plate

Note: Maximum Hydraulic Pressure (Max Hydr Press) refers to the recommended pressure limit to avoid putting undue stress on the equipment (even if the forklift can lift more) to prevent damage or dangerous situations.

The data plate is generally located in a visible area from the driver’s seat, such as on the mast or the control console. It may be made of metal or another durable material. This plate displays clear information, often engraved or printed in easily readable characters. It provides critical details about the forklift:

- The forklift manufacturer’s name.

- The forklift model number. This information is useful when ordering replacement parts or looking up model-specific information.

- The serial number identifies the forklift and is used for tracking and maintenance.

- The forklift’s weight specifies the vehicle’s weight.

- The forklift’s rated capacity or maximum load can lift at a specified height and center of gravity distance.

- The maximum lift height at which the forklift can raise a load.

- The center of gravity distance, expressed in inches or millimetres, refers to the distance between the load’s center of gravity and the heel of the forks.

Various diagrams, curves, or illustrations may also be visible near or on the data plate. They are essential for determining the forklift’s actual capacity in different situations.

How Can External Factors Alter Your Forklift’s Load Capacity?

In addition to factors intrinsic to the forklift and its load, several external factors can also reduce its load capacity and compromise its stability. Operating the vehicle on uneven or unstable ground can impact its load capacity. The forklift’s stability is reduced on sloped or slippery terrain, directly decreasing its adequate load capacity. On unstable surfaces such as gravel or sand, the risk of tipping increases, requiring lighter loads to avoid accidents.

It is crucial to ensure that the forks are suitable for the forklift’s lifting capacity:

- For safety reasons, if the forks can support less than the forklift, their lifting capacity must be that of the forks.

- If the forklift can lift less than the forks, the lifting capacity must match that of the forklift.

Weather conditions like rain, snow, or ice can make the ground slippery and reduce the forklift’s stability. These operating conditions directly impact its load capacity. For example, in strong winds, a load lifted to a great height can become unstable, especially if it is bulky, reducing the safe load the forklift can handle. Poorly balanced loads with an off-center center of gravity can also compromise the forklift’s balance, reducing its lifting capacity and increasing the risk of tipping.